Heavy Machinery Predictive Maintenance Tokens: The Future of Industrial Efficiency

Imagine a world where heavy machinery operates at peak efficiency, with minimal downtime and reduced maintenance costs. Sounds like a utopian fantasy, but what if we told you that predictive maintenance tokens can make this a reality?

As seen in the likes of Elon Musk’s innovative ventures, the convergence of cutting-edge technologies like AI, IoT, and machine learning is transforming the way we approach industrial maintenance. Heavy machinery predictive maintenance tokens are at the forefront of this revolution, promising to disrupt traditional maintenance practices and unlock unprecedented efficiency gains.

The State of Industrial Maintenance Today

The current state of industrial maintenance is reactive, with most companies adopting a “fix-it-when-it-breaks” approach. This not only leads to costly downtime but also compromises safety, reduces productivity, and negatively impacts the environment.

A study by the McKinsey Global Institute estimates that predictive maintenance can reduce maintenance costs by up to 40% and increase productivity by up to 25%. The potential for growth is staggering, and heavy machinery predictive maintenance tokens are poised to lead the charge.

How Predictive Maintenance Tokens Work

Predictive maintenance tokens utilize advanced algorithms, IoT sensors, and machine learning to monitor equipment performance in real-time. This enables maintenance teams to identify potential issues before they occur, schedule proactive maintenance, and optimize machine performance for maximum efficiency.

By leveraging blockchain technology, predictive maintenance tokens create a secure, transparent, and tamper-proof record of equipment performance data. This not only enhances trust among stakeholders but also enables more accurate predictive modeling.

Key Benefits of Predictive Maintenance Tokens

- Reduced Downtime: Predictive maintenance tokens enable proactive maintenance, reducing downtime and increasing overall equipment effectiveness.

- Cost Savings: By reducing maintenance costs, companies can allocate resources more efficiently, leading to increased profitability.

- Improved Safety: Predictive maintenance tokens help identify potential safety risks, reducing the likelihood of accidents and ensuring a safer work environment.

- Enhanced Productivity: With optimized equipment performance, companies can increase production capacity, leading to increased revenue and competitiveness.

Real-World Applications of Predictive Maintenance Tokens

The likes of General Electric and Siemens are already leveraging predictive maintenance tokens to transform their industrial operations. For instance, GE’s Predix platform uses advanced analytics and machine learning to optimize equipment performance.

Similarly, Siemens’ MindSphere platform utilizes IoT sensors and advanced analytics to provide real-time insights into equipment performance. These real-world applications demonstrate the enormous potential of predictive maintenance tokens in driving industrial efficiency.

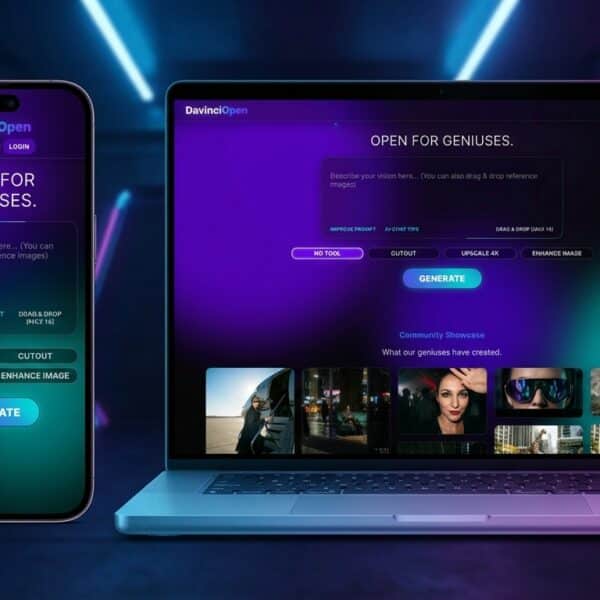

The Role of TokenRobotic in Heavy Machinery Predictive Maintenance

As a pioneer in the predictive maintenance token space, TokenRobotic is committed to empowering companies to unlock the full potential of their heavy machinery. By leveraging cutting-edge technologies and expertise, TokenRobotic provides a comprehensive suite of solutions designed to optimize equipment performance, reduce downtime, and enhance safety.

Discover more on TokenRobotic and how their innovative approach to predictive maintenance tokens is revolutionizing the industrial landscape.

Conclusion

In conclusion, heavy machinery predictive maintenance tokens hold the key to unlocking unprecedented industrial efficiency. As the industry continues to adopt these innovative solutions, we can expect to see transformative changes in the way companies approach maintenance, and the role of TokenRobotic in this emerging industry.

Ready to unlock the full potential of your heavy machinery? Discover more on TokenRobotic today!