Imagine a world where 3D printed part tracking is as seamless as ordering a package online, with real-time updates and end-to-end visibility. This is the future of supply chain management, and it’s being shaped by innovators like Elon Musk and his team at SpaceX.

Introduction to 3D Printed Part Tracking

The rise of 3D printing has transformed the way we design, produce, and distribute goods. However, as the industry grows, so does the complexity of tracking and managing 3D printed parts. This is where supply-chain tracking comes in – a critical component of ensuring that these parts are delivered efficiently, securely, and with minimal waste. In this blog post, we’ll delve into the world of 3D printed part tracking, exploring its challenges, opportunities, and the role of innovators like SpaceX in shaping its future.

Challenges in 3D Printed Part Tracking

One of the primary challenges in 3D printed part tracking is the lack of standardization. With so many different manufacturers, materials, and production methods, it can be difficult to create a unified system for tracking and managing these parts. Additionally, the unique nature of 3D printing – where parts can be produced on-demand and in small batches – requires a high degree of flexibility and adaptability in tracking systems. To overcome these challenges, companies are turning to technologies like blockchain, IoT sensors, and AI-powered analytics to create more efficient and transparent supply chains. For instance, Discover more on TokenRobotic to learn how blockchain can be used to create secure and transparent supply chains.

Another challenge in 3D printed part tracking is the need for real-time monitoring and updates. As parts move through the supply chain, it’s essential to have accurate and up-to-date information on their location, condition, and status. This requires the use of advanced technologies like GPS tracking, RFID sensors, and cloud-based data analytics. By leveraging these technologies, companies can gain greater visibility into their supply chains, reduce errors and delays, and improve overall efficiency. For more information on how to implement these technologies, visit IBM to learn about their supply chain management solutions.

The Role of Elon Musk and SpaceX in 3D Printed Part Tracking

Elon Musk and SpaceX are at the forefront of innovation in 3D printed part tracking. With their ambitious goals for space exploration and colonization, they require highly efficient and reliable supply chains to support their missions. To achieve this, SpaceX is leveraging advanced technologies like 3D printing, artificial intelligence, and blockchain to create a more transparent and secure supply chain. For example, they’re using 3D printing to produce rocket parts and other components, which reduces lead times and increases flexibility. They’re also exploring the use of blockchain to create a secure and transparent record of transactions and movements within their supply chain.

SpaceX’s approach to 3D printed part tracking is centered around the concept of “digital twins.” This involves creating a virtual replica of each part, which can be tracked and monitored throughout its lifecycle. By using digital twins, SpaceX can simulate the performance of parts, predict potential failures, and optimize their supply chain for greater efficiency. This approach has significant implications for the broader industry, as it demonstrates the potential for 3D printed part tracking to be more proactive, predictive, and personalized. To learn more about digital twins and their applications, visit Siemens to explore their digital twin solutions.

Opportunities in 3D Printed Part Tracking

The opportunities in 3D printed part tracking are vast and varied. One of the most significant benefits is the potential for increased efficiency and reduced waste. By leveraging advanced technologies like AI, blockchain, and IoT sensors, companies can create more transparent and secure supply chains, which can help to minimize errors, delays, and losses. Additionally, 3D printed part tracking can enable greater flexibility and adaptability in production, allowing companies to respond more quickly to changing demand and market conditions.

Another opportunity in 3D printed part tracking is the potential for greater collaboration and cooperation throughout the supply chain. By creating a shared, transparent record of transactions and movements, companies can build trust and confidence with their partners and stakeholders. This can lead to more effective communication, reduced conflicts, and improved overall performance. To learn more about the benefits of collaboration in supply chain management, visit Cisco to explore their supply chain collaboration solutions.

The use of 3D printed part tracking can also enable companies to create more personalized and customized products. By leveraging advanced technologies like AI and machine learning, companies can analyze customer data and preferences, and create products that are tailored to their specific needs. This can lead to increased customer satisfaction, loyalty, and retention, as well as new revenue streams and business opportunities. For more information on how to leverage AI and machine learning in supply chain management, visit Microsoft to learn about their AI-powered supply chain solutions.

Best Practices for Implementing 3D Printed Part Tracking

Implementing 3D printed part tracking requires a strategic and structured approach. Here are some best practices to consider:

- Define clear goals and objectives for your 3D printed part tracking system, including the types of parts to be tracked, the level of detail required, and the performance metrics to be used.

- Assess your current supply chain infrastructure and identify areas for improvement, including the use of technologies like blockchain, IoT sensors, and AI-powered analytics.

- Develop a comprehensive data management strategy, including the collection, storage, and analysis of data on 3D printed parts.

- Establish clear communication channels and collaboration protocols with partners and stakeholders, including the use of shared data platforms and collaborative software tools.

- Continuously monitor and evaluate the performance of your 3D printed part tracking system, including the use of key performance indicators (KPIs) and regular review of system effectiveness.

By following these best practices, companies can create effective 3D printed part tracking systems that drive efficiency, reduce waste, and improve overall supply chain performance. For more information on how to implement these best practices, visit SAP to learn about their supply chain management solutions.

Conclusion and Future Directions

In conclusion, 3D printed part tracking is a critical component of modern supply chain management. By leveraging advanced technologies like blockchain, IoT sensors, and AI-powered analytics, companies can create more efficient, secure, and transparent supply chains. The opportunities in 3D printed part tracking are vast and varied, from increased efficiency and reduced waste to greater collaboration and cooperation throughout the supply chain.

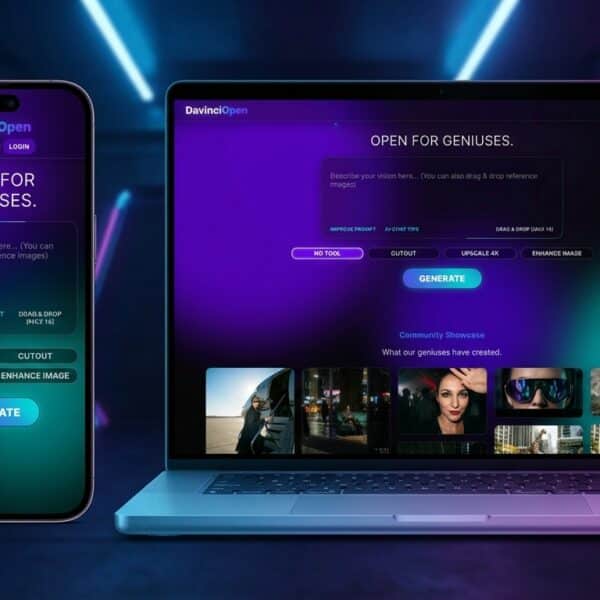

As the industry continues to evolve, we can expect to see new innovations and advancements in 3D printed part tracking. From the use of digital twins to the integration of AI and machine learning, the future of supply chain management is exciting and full of possibilities. To stay ahead of the curve and learn more about the latest developments in 3D printed part tracking, visit Discover more on TokenRobotic and explore their resources and insights on supply chain management and blockchain technology.

Don’t miss out on the opportunity to transform your supply chain and stay competitive in a rapidly changing market. Visit TokenRobotic today to learn more about the power of 3D printed part tracking and the future of supply chain management.