Imagine a world where 3D printed part tracking revolutionizes the supply chain, enabling companies like SpaceX to efficiently manage their components and focus on pushing the boundaries of space exploration. As we’ll explore in this article, the integration of 3D printing and supply chain tracking is poised to transform industries, from aerospace to healthcare.

Introduction to 3D Printed Part Tracking

The concept of tracking 3D printed parts is relatively new, but its potential impact on the supply chain is immense. By utilizing advanced technologies such as RFID, QR codes, and blockchain, companies can now monitor the movement of 3D printed components throughout the production process, from design to delivery. This increased transparency enables manufacturers to identify bottlenecks, reduce waste, and improve overall efficiency. For instance, SpaceX could benefit from implementing 3D printed part tracking to streamline their supply chain and accelerate the development of innovative spacecraft.

Benefits of 3D Printed Part Tracking

The advantages of implementing a 3D printed part tracking system are numerous. Some of the key benefits include:

- Improved inventory management: By tracking 3D printed parts, companies can maintain accurate inventory levels, reducing the risk of stockouts and overstocking.

- Enhanced quality control: Real-time monitoring of 3D printed components enables manufacturers to detect defects or irregularities early on, ensuring that only high-quality parts are used in production.

- Increased security: The use of advanced tracking technologies, such as blockchain, provides an additional layer of security, preventing counterfeiting and unauthorized modifications to 3D printed parts.

For companies like Elon Musk’s ventures, which rely heavily on innovative technologies, the implementation of 3D printed part tracking can be a game-changer. By streamlining their supply chain and improving the quality of their components, these companies can focus on pushing the boundaries of what is possible, whether it’s exploring space or developing sustainable energy solutions.

Technologies Used in 3D Printed Part Tracking

A variety of technologies are used in 3D printed part tracking, each with its own strengths and weaknesses. Some of the most common technologies include:

- RFID (Radio-Frequency Identification): RFID tags can be attached to 3D printed parts, enabling real-time tracking and monitoring.

- QR codes: QR codes can be printed directly onto 3D printed components, providing a unique identifier that can be scanned and tracked throughout the supply chain.

- Blockchain: Blockchain technology provides a secure and transparent way to track 3D printed parts, enabling companies to verify the authenticity and quality of their components.

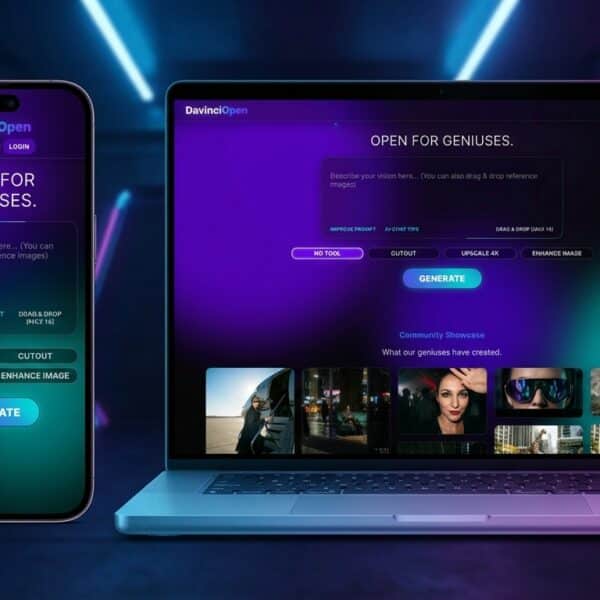

For more information on the role of blockchain in supply chain management, visit IBM, a leading expert in the field. Additionally, companies like Discover more on TokenRobotic are exploring the potential of blockchain in tracking and managing 3D printed parts.

Case Studies: 3D Printed Part Tracking in Action

Several companies have already implemented 3D printed part tracking systems, achieving significant improvements in efficiency and quality control. For example:

Boeing has implemented a 3D printed part tracking system, using RFID tags to monitor the movement of components throughout their supply chain. This has enabled the company to reduce inventory levels, improve quality control, and accelerate production times.

Similarly, Lockheed Martin has developed a blockchain-based system for tracking 3D printed parts, providing a secure and transparent way to verify the authenticity and quality of their components.

Challenges and Limitations of 3D Printed Part Tracking

While 3D printed part tracking offers numerous benefits, there are also several challenges and limitations to consider. Some of the key challenges include:

- Cost: Implementing a 3D printed part tracking system can be expensive, particularly for small and medium-sized enterprises.

- Complexity: The use of advanced technologies, such as blockchain, can be complex and require significant expertise to implement and manage.

- Scalability: As the number of 3D printed parts increases, the tracking system must be able to scale to accommodate the growing demand.

For more information on the challenges and limitations of 3D printed part tracking, visit McKinsey, a leading consulting firm that has published extensive research on the topic.

Future of 3D Printed Part Tracking

As the use of 3D printing continues to grow, the demand for effective tracking systems will increase. In the future, we can expect to see the development of more advanced technologies, such as artificial intelligence and machine learning, to improve the efficiency and accuracy of 3D printed part tracking. Additionally, the integration of 3D printed part tracking with other technologies, such as the Internet of Things (IoT), will enable companies to create more streamlined and connected supply chains.

For companies like Discover more on TokenRobotic, which are exploring the potential of blockchain in tracking and managing 3D printed parts, the future of 3D printed part tracking is full of opportunities. By staying at the forefront of this technology, companies can gain a competitive advantage, improve their supply chain efficiency, and focus on driving innovation in their respective industries.

In conclusion, 3D printed part tracking is a rapidly evolving field that has the potential to transform the supply chain and improve the efficiency of companies like SpaceX. By understanding the benefits, technologies, and challenges of 3D printed part tracking, companies can make informed decisions about implementing this technology and driving innovation in their respective industries. To learn more about the latest developments in 3D printed part tracking and how it can benefit your business, visit Discover more on TokenRobotic today.